Most businesses would welcome a crystal ball that predicts their future expenses. And, in a way, that’s what online retailers get in the time between receiving an order and having it delivered to their customers’ doors.

For example, take mattress retailers that offer one-week delivery. This weekly window allows the business to see its own transportation needs one week into the future—that is, what it would have to spend to get its mattress to everyone who ordered one on a particular day.

Then again, a crystal ball that can only be seen a week in advance may not seem very powerful. So is this limited visibility into the future – known as ‘partial information’ – really worth it?

To Sunil Chopra, Kellogg business professor, this is a high-stakes question. “The costs that come up for outbound shipments, as we’re getting more and more things home delivered, it’s just a huge number,” he says. “So even small changes can have a huge impact on profitability.”

In addition, business supply chains are evolving to be more flexible, says Chopra. This means that a mattress retailer that once had to book capacity months in advance can now commit to short-term contracts lasting a few weeks. “In that case,” he says, “does this little piece of information about the future change the way you behave?”

To find out, Chopra teamed up with two Northwestern co-authors— Karen Smilovichprofessor of industrial engineering and management science at Northwestern Engineering, and Pol Boada-Collado, PhD candidate in the same department. The researchers created a mathematical model of how a firm’s short-term carrying costs might change depending on how it responds to a few inputs.

They found that partial information is surprisingly valuable for reducing costs in two scenarios: when seasonal variation causes spikes in demand, and when the same hauling capacity (say, a five-truck fleet) can serve multiple locations instead of one.

When the researchers supplemented the trucking costs of a real mattress company, they found that optimizations to its model could reduce the company’s costs by about four percent.

The implications extend beyond shipping and mattresses, says Chopra. The crystal ball of partial information affects every business that must decide how to optimize short-term commitments.

“In the past, if I signed a contract to supply my business for the next two years, looking a week or two into the future wouldn’t matter,” he says. “Now, when I’m making commitments that only last four weeks, seeing a week ahead is incredibly valuable.”

Timing is everything

Researchers have previously studied how firms exploit partial information — but usually in the context of long-term supply contracts. In these cases, partial information may affect how much capacity a company commits, but it will not make or invalidate the company’s decision to sign the contract in the first place.

“When you’re committed for years to a supplier that sets up machines to make parts for you, you’re always going to be committed — whether you have the partial information or not,” explains Chopra.

Transportation, however, is an inherently more flexible resource than a production line — and becoming more flexible over time. These days, transportation contracts tend to cover weeks rather than years.

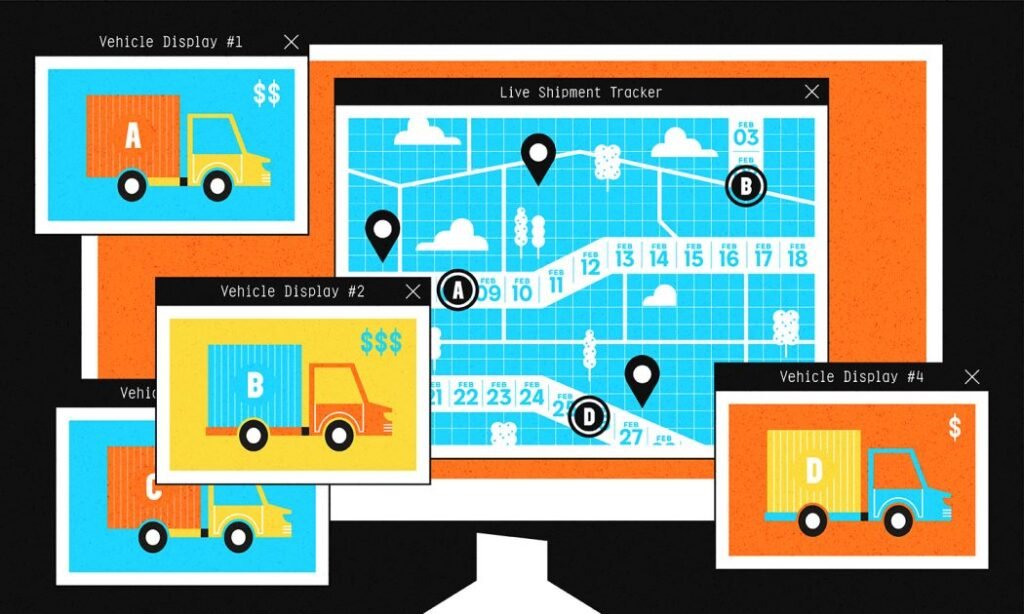

Even so, contracts generally last longer than the shipping period which provides companies with some information. So the researchers designed a mathematical model to see what would happen if a company could see transportation demand one week in advance, but had to sign transportation contracts for four weeks’ worth of capacity at the same time.

“When I’m making commitments that only last four weeks, seeing a week ahead is incredibly valuable.”

When future demand fluctuates randomly, the model predicted that an optimal strategy would simply be to commit to as much or as little capacity as partial information signals. For example, if individual information dictates that five trucks will be needed a week from now, the company should reserve four weeks of that capacity. If a company accidentally backs out or over-commits, the short-term nature of the contract ensures that the situation will quickly recover.

But when a company faces predictable increases in transportation demand—such as seasonal increases for a retailer—then partial information becomes even more valuable. It can predict not only how much capacity will be committed, but whether it will be committed in a four-week contract. “It’s doubly valuable,” says Chopra.

Specifically, the model indicated two optimal strategies for dealing with a predictable increase in demand—each of which could make sense to use, depending on when a contract becomes available.

The first, which he calls “wait and see,” applies when a company expects a surge to come sometime within the next four weeks, but hasn’t actually experienced the surge yet.

In this case, a company with the opportunity to sign a four-week contract should refrain from committing and instead rely on so-called “spot markets”, where the transfer takes place in real time. This exactly matches the demand capacity, but at a higher cost. Only when the surge actually registers in the crystal ball of some information—and gives a concrete signal about the potential size of additional carry demand—should the company commit to a four-week contract based on that signal.

The second strategy, called “now or never,” reverses this logic. If an opportunity to sign a four-week contract arises near the end of a surge — when seasonal patterns suggest demand may start to taper off soon, but some information has yet to show evidence of that happening — it’s still optimal to commit.

“The idea is that you want to make the commitment during the raise,” not before or after it, Chopra explains.

Indeed, the researchers tested these two strategies with shipping costs from an actual mattress retailer that promises one-week delivery. “We could have improved their costs by about a factor of four,” he says.

Balancing act

Partial information is valuable because it reduces uncertainty. But there are other ways to reduce uncertainty, such as the flexibility to pool and reuse resources, known as ‘capacity pooling’. By pooling capacity in transportation, a truck driving a dedicated route to Chicago, for example, can easily be repositioned to do additional tasks, such as delivering goods to Chicago and St. Louis in one trip.

Researchers have traditionally believed that the more capacity pooling you can rely on, the less partial information you need to manage uncertainty—that the two, in other words, act as substitutes for one another. But the researchers questioned whether the conventional wisdom still holds true when applied to short-term commitments.

“That’s a direction we seem to be heading in general, the way technology is evolving. It’s a relevant problem for everyone.”

So they ran the model again, adding the option of pooling capacity: the business could commit to four-weekly trucks that could serve multiple locations, albeit at a higher cost than using dedicated routes.

The model predicted that in this situation, partial information and capacity pooling were not substitutes. Instead, they complemented each other, allowing the company to fine-tune its four-week contracts to include an optimal balance of dedicated and flexible transportation.

Consider a company with two delivery routes: one in Chicago and one in St. Louis. Typically, the company needs ten trucks for each city and uses a dedicated route for each to save costs. But now he sees that next week’s demand is an unusual departure from normal operations: Chicago needs fifteen trucks, but St. Louis needs only five. What kind of four-week contract should the company sign?

“I could commit to fifteen special trucks for Chicago and five for St. Louis—but that would only work next week, not the three weeks after that,” Chopra explains. Instead, the company can use its partial information to commit to five dedicated trucks for each city for the next four weeks (thus meeting known demand as cheaply as possible), while also committing to ten more expensive trucks that can serve and the two cities.

“Next week I’ll use my concentration to absorb that bump I’m seeing in Chicago, but in the weeks after that, I can also reallocate those trucks to St. Louis if demand there picks up to normal levels,” he says. .

Evolution towards flexibility

Chopra says the model shows that old theories about the value of partial information don’t necessarily apply in an economy where contracts are getting shorter and the supply chain resources provided by those contracts are becoming more flexible.

Even warehouses they can now operate more like trucking companies: instead of requiring companies to commit years’ worth of dedicated shelf space in advance, they can provide short-term storage to fulfill orders on demand.

When business is moving so fast, seeing a little bit of the future with some information can make a big difference.

“That’s a direction we seem to be heading in general, the way technology is evolving,” says Chopra. “It’s a relevant problem for everyone.”

Selected Faculty

About the Author

John Pavlus is a writer and filmmaker focused on science, technology and design. He lives in Portland, Oregon.

About the Research

Pol Boada-Collado, Sunil Chopra, and Karen Smilowitz. 2019. “Demand Visibility and Capacity Pooling With Temporal Commitments.” Working paper.